Navigating Last-Minute Design Changes for a Perfect Y2K Leather Bomber Jacket

- Sheré Daniels

- Oct 22, 2025

- 2 min read

Creating a custom leather bomber jacket for a sorority group became a challenging journey that highlighted the importance of following a clear development process. The project involved three different design ideas, skipped sampling phases, and last-minute production changes. This experience offers valuable lessons about why rushing design and production can lead to setbacks, and how sticking to a proven process ensures better results.

Starting Without a Fit Sample

The project began with a tight deadline. The client waited until the last moment to start the jacket development and decided to skip the sampling phase entirely. Normally, a fit sample is essential to check how the jacket fits and feels before moving to production. The client was asked to send a fit sample for reference, but it never arrived.

Without a fit sample, the team had to improvise. They extracted measurements from an existing unisex leather bomber jacket to approximate the fit the client wanted. This approach was far from ideal because the original jacket was not tailored to the sorority’s specific needs or style preferences.

This step shows how critical it is to have a physical reference or detailed specs from the customer. Without these, the risk of fit issues grows, especially when rushing to meet deadlines.

Following the Tech Pack Exactly but Facing Design Changes

The jacket was produced exactly according to the tech pack provided by the client. Despite this, once the first version was completed, the client was unhappy with the design. They requested moving text around and changing the overall direction of the jacket’s look. The team agreed to these changes, even though making design adjustments during production is not standard practice. This decision was made to accommodate the client’s wishes and try to deliver a product closer to their vision.

Multiple Reiterations During Production

After the second version, the client still wasn’t satisfied. This back-and-forth during production caused delays and added complexity. Typically, design changes happen during sampling, not production, because changes at this stage are costly and time-consuming.

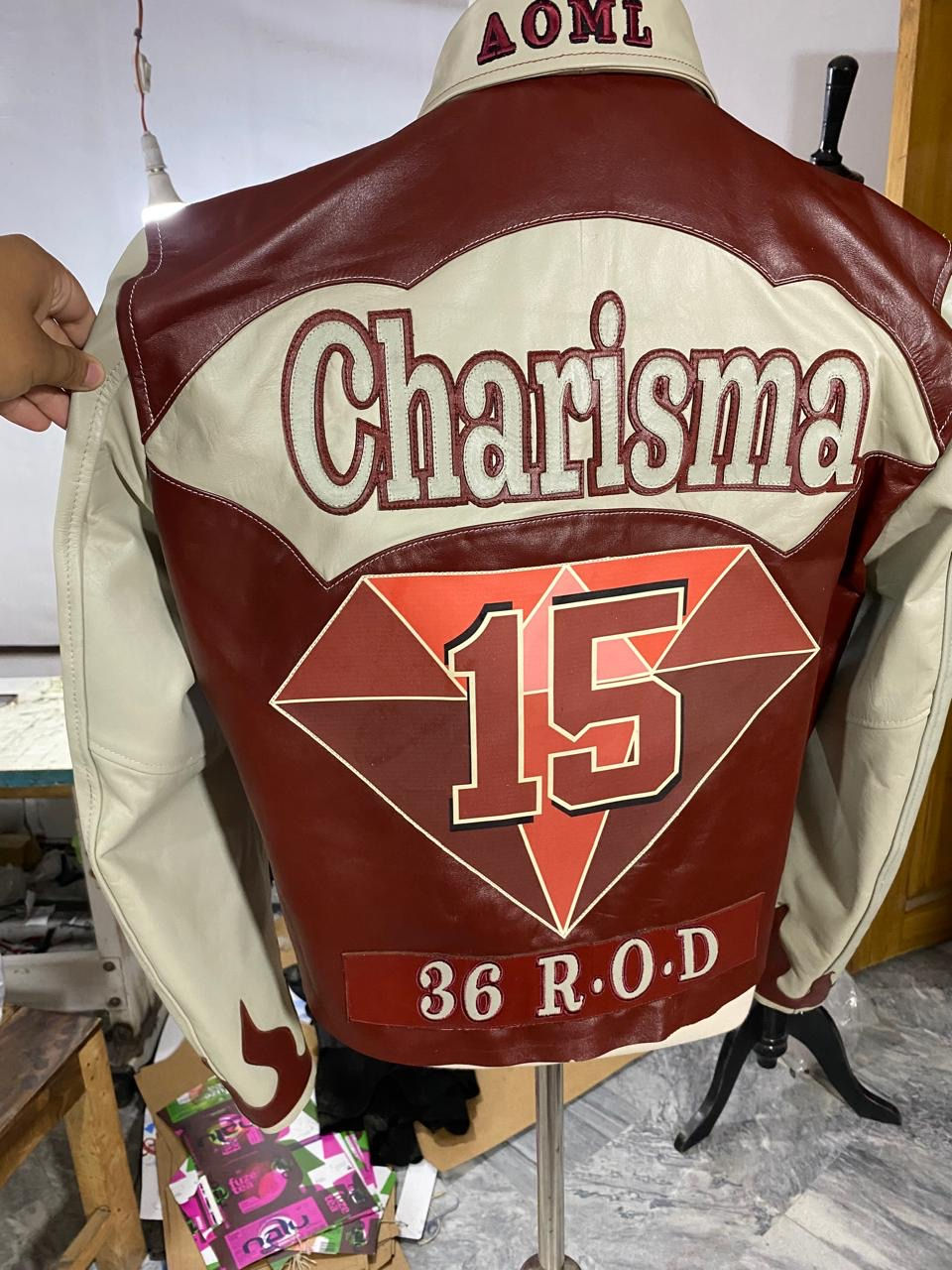

The team worked tirelessly to perfect custom UV leather prints, direct embroidery, and patchwork. These details required precision and time, but the rushed timeline and lack of early feedback made the process difficult.

Finally, after the third reiteration, the client and the team reached an agreement on the design. The jacket reflected a blend of the client’s vision and the team’s craftsmanship.

Lessons Learned About Development and Timing

This project reinforced several important lessons:

Sample development is crucial. Skipping this phase increases the chance of fit and design issues.

Clear communication and early feedback save time. Waiting until production to make changes causes delays and extra costs.

Providing fit samples or detailed specs is essential. Without these, manufacturers must guess, which can lead to errors.

Rushing the process leads to compromises. Development takes time and cannot be rushed without consequences.

Moving Forward with Confidence

The final jacket is a testament to the hard work and flexibility of the team, but it also serves as a reminder that the best results come from following a structured development process. For anyone planning custom apparel, especially complex pieces like leather bomber jackets, starting early and allowing time for sampling and fit testing is key.

Comments